The Single Point Diamond Dresser proves its exceptional versatility as an indispensable tool for both turning and dressing grinding wheels. These dressers are crafted with meticulous precision, utilizing handpicked raw diamonds securely affixed within holders through specialized bonding techniques. Functioning as a reliable companion to your grinding wheel, this dressing tool serves a dual purpose: firstly, it expertly eliminates abrasive grains that have reached the end of their lifespan, and secondly, it masterfully restores the grinding wheel’s precise geometric contours. Our offering includes three distinct grades tailored to rejuvenate your wheel when it inevitably loses its sharpness. Over time, the interstitial spaces between the grains tend to accumulate the material being ground, necessitating this essential maintenance step.

We are one of the leading manufacturers of Single Point Diamond Dresser to customers. As an exporter of Single Point Diamond Dresser, our product line is widely utilised in the diamond industry. This product is widely used in the diamond cutting industry as well as other sectors. As a wholesale supplier of Single Point Diamond Dresser, we can assure you that it is free of faults, requires no maintenance, and is among the best quality dressers available.

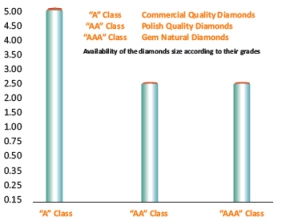

Single Point Diamond Dressers – SELECTION OF THE DIAMONDS

The choice of diamonds relies on various factors, including the size of the grinding wheel, its hardness, grit size, abrasive type, and the specific dressing task at hand. To guide you in selecting the appropriate diamond size, we propose the following rule of thumb:

(Radius of wheel+width) x 0.004 = Carat size of diamond (1 Carat = 0.2 gm)

| GRINDING WHEEL GRIT SIZE |

FEED RATE IN mm/rev |

| 30 – 46 | 0.60 -0.30 |

| 50 120 | 0.30 0.10 |

| 180 320 | 0.10 0.02 |

|

||||

| Diameter | Width | Carat Size | ||

| 100 | 12 | 0.25 | ||

| 150 | 12 | 0.30 | ||

| 175 | 12 | 0.50 | ||

| 250 | 40 | 0.75 | ||

| 350 | 25 | 1.00 | ||

| 350 | 30 | 1.25 | ||

| 350 | 50 | 1.50 | ||

|

||||

| Diameter | Width | Carat Size | ||

| 450 | 50 | 1.75 | ||

| 600 | 50 | 2.00 | ||

| 600 | 75 | 2.50 | ||

| 600 | 150 | 3.00 | ||

| 750 | 75 | 3.00 | ||

| 750 | 100 | 3.50 | ||

| 900 | 75 | 4.00 | ||