Industrial Diamond Tools hard-bonded and ceramic-bonded blades are suitable for a variety of tasks, including cutting soft abrasive materials. The diamond grains and segments are kept secure in the cutting tool, avoiding premature wear. The material they are made from is a mix of natural and synthetic industrial diamond. Different grain sizes and shapes are used for different applications. The following are some of the advantages of using industrial diamond tools.

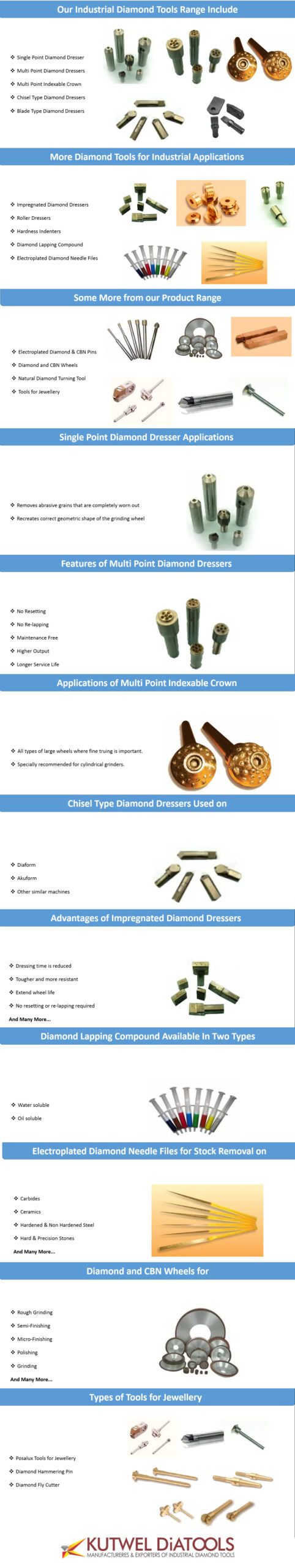

Features of Industrial Diamond Tools

These tools are designed to sharpen and polish a wide range of surfaces. They are durable and can be used for a variety of applications. They are a good choice for a variety of industries. The main advantage of using diamond tools is their ability to reduce heat, which minimizes the risk of cracks and burns on work pieces. In addition, diamonds have a high tensile strength, which makes them a superior choice for cutting metal.

How to Choose Industrial Diamond Tools?

When choosing a diamond for a cutting application, its quality is very important. Various factors determine the diamond’s quality, such as the shape and size. A trained diamond expert can assess the quality of a diamond by measuring its performance. A higher quality diamond will have more cutting points, better structure, and a more effective dressing action. An octahedron is an eight-sided diamond with six cutting points. Octahedrons are generally used in single-point tools and cluster tools.

Taking Care of Industrial Diamond Tools

Proper care is essential for diamond dressing tools. By following a few simple rules, these tools will last for many years while delivering trouble-free performance. In addition, proper maintenance will prevent gouging of the wheel and chatter marks on the finished work. A dull diamond causes excessive friction and glazes the grinding wheel. By sharpening the dressing area, the usable life of a diamond will increase. If you don’t follow these tips, it will be difficult to ensure a consistent quality finish.

What to keep in Mind when Buying Industrial Diamond Tools?

When purchasing diamond tools, it’s crucial to consider the type of material they’ll be processing. For example, diamond tools are not suitable for steels, since they will react with Fe, Co, Ni, Cr, and V. The diamond in the tool should be able to resist these types of materials. If you need to process a more abrasive material, you should use a more expensive tool. In addition to abrasive materials, industrial diamond tools should be made of durable materials.

The Bottom Line

Polycrystalline diamond tools are highly durable and are ideal for high-abrasion processes. They are also extremely durable and can be used in a variety of applications. They can be manipulated to create the desired angles and planes. They are also very flexible. They can be adjusted to a desired angle. This flexibility makes these diamond tools a very valuable addition to any industrial environment. Aside from being durable, they are also highly affordable.