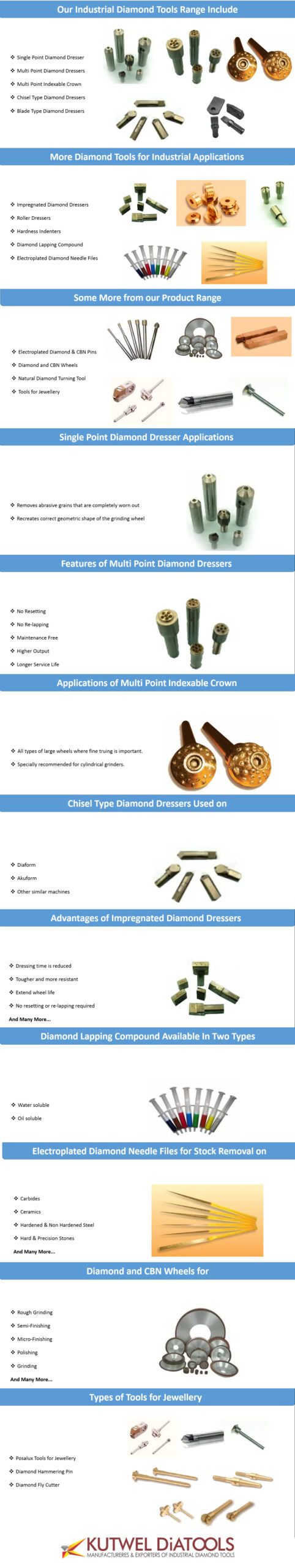

A multi-point diamond dresser is a machine for dressing precision grinding wheels. These machines have numerous points and are suitable for both resin bonded and vitrified wheels. Diamond dressing tools are available in different varieties like platelets, and monocrystalline diamond MKD. Monocrystalline diamond is more wear-resistant and stable than polycrystalline diamond. They can also be used as wheel straightening tools. Let’s look at some of the important features of a multi-point diamond dresser.

Donut Clusters Diamond Dresser

A Multi-Point Diamond Dresser is often a great option for grinding large wheels because of its donut-like pattern. These diamond dressers come in different configurations and have different specifications, such as carat weight, size, and geometry. Listed below are the key differences between the two types of multipoint dressers. If you’re interested in buying a donut-like dresser for your shop, read on.

A Multi-Point Diamond Dresser features clusters of tiny natural diamonds set in a geometric pattern or single layer. These diamonds are bonded into a wear-resistant bond. These diamonds are perfect for the coarse dressing of grinding wheels, removing imbalance, and achieving a uniform surface. In comparison to a Single Point Diamond Dresser, this type is more economical but is still a very effective tool.

Rotary Diamond Dressers

There are two main types of rotary diamond dressers: single-point and multi-point. Single-point diamond dressers are used to dress wheels with a straight profile, while multi-point dressers are used to dress wheel segments with a complex profile. Depending on the type of rotary dresser, diamonds may be set in single layers, in multiple layers, or throughout the wheel. There are also special variants for thread forms.

There are many benefits of rotary dressers. They are fast and can generate complex profiles. Compared to classic dressers, rotary tools suffer less wear. Some designs are ideal for internal grinding while others work best for small grinding wheels. Here are some of the advantages of using a rotary diamond dresser. Once you have decided which type of diamond dresser is right for your application, you can begin shopping for the best tool for your needs.

Rotary Chisel Diamond Dressers

When buying a diamond dresser, you should always choose a high-quality, rotary chisel. They are used for many tasks and come in different styles. They are generally cheaper per carat than large stones. In addition, rotary chisels wear evenly and rarely break until used up. To find the right rotary chisel, you need to understand a few things about the diamond dresser.

Blade Type Diamond Dressers are the most expensive type of dresser, but you can also buy inexpensive single-point versions. They are popular because they offer several benefits. For example, they are more affordable than other types of dressers. They also come with multiple blades and cutting edges, which will meet your business needs. They are durable and come in a variety of prices, making them a great option for any budget.

Rotary Profile Diamond Dressers

A rotary diamond dresser profile is a two-dimensional topography that allows comparison between two states of wear. This wear profile is calculated using geometrical parameters, including wear height. A wear profile should overlap and be stable to be used for this comparison. A Python application was used to calculate these parameters. The two overlapping profiles indicate that a rotary dresser has suffered wear. A similar profile can be obtained with the same diamond density but at a lower height.

The lower pit radius allows for a more efficient dressing process. A rotary dresser with a half-pit radius was 31% more efficient than one with a one-half pit radius. This means that the amount of material removed by the dresser is higher than programmed. It also results in a better surface finish, which is important for quality finishing. This study was supported by several publications and will be published in a future issue of the Journal of Diamond Grinding.

Rotary Disc Diamond Dressers

A rotary disc multi-point diamond dresser is a machine used to true vitrified CBN wheels. This equipment has many benefits over other types of dressing machines. It has a large dressing area and can increase feed safely. Some have 24 or 36 diamonds in each head, respectively. They are highly customizable and can meet any application’s needs. If you need to dress a single point diamond or multiple points, you can also buy a cluster tool.

The diamond particles are chemically and galvanically bonded to the dresser body and are arranged on its face and circumferential edges in an oblong pattern. These diamonds are then arranged on all wheels, except those with the narrowest diameter, to achieve the optimum abrasion. The schematic drawings illustrate how the invention works. A rotary disc multi-point diamond dresser is designed to be highly accurate, so precision is critical.

The Bottom Line

These different types of diamond dresser like donut clusters diamond dresser, rotary diamond dressers, rotary chisel, rotary profilediamond dresser, and rotary discdiamond dresser are all tools that help with profiling, and finishing of diamonds, and are must when working with different types and sizes of diamonds.